Peng Hui Energy Zhang Guiping: Application analysis of PAA adhesive in energy storage batteriesIssuing time:2023-10-09 12:51 Lithium battery binder is a very important part of the positive and negative electrode materials of lithium battery, which can bond the active substance, conductive agent and fluid collector in the electrode material tightly. With the continuous increase of China's new energy development efforts, the domestic production of lithium-ion batteries continues to grow, and the use of lithium battery binders is also increasing. The explosion of energy storage, but also let the adhesive market become in short supply in the future, and major manufacturers are also eager to exit their own new technology. Recently, at the 2023 starting energy storage battery technology Forum, Zhang Guiping, vice president of Penghui Energy Research Institute, delivered a keynote speech on the application analysis of PAA adhesives in energy storage batteries, showing the latest technology of Penghui Energy from the aspects of PAA introduction, technical characteristics advantages and cases.

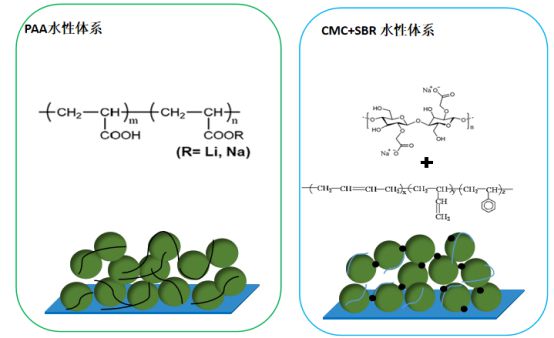

Photo: Zhang Guiping, Vice President of Penghui Energy Research Institute The following is the text of the speech: PAA adhesives, referred to as sodium polyacrylate, have better adhesion than traditional commonly used adhesives such as carboxymethyl cellulose (CMC) and styrene butadiene rubber (SBR), thus inhibiting the separation of the electrode active material between the powder and the electrode coating and the fluid collector, thereby inhibiting the expansion of the electrode active material during charge/discharge. A single PAA solution adhesive can be prepared to replace the CMC/SRB double adhesive, thus simplifying the pulping process. In addition, a thinner and more uniform solid electrolyte interface (SEI) film can be formed, and electrode deformation is also prevented to ensure an excellent charge/discharge cycle life of the power battery. From the chemical mechanism analysis, why is PAA better than SBR, CMC? Because the PAA polysodium acrylate binder has a molecular structure of sodium acrylate or lithium acrylate group, after adding an excessive 5N NaOH solution, stir for 2 hours to replace the methyl in the methyl acrylate with Na ions. The stripping test is then performed at 180°, and the applied force until the tape is stripped is measured while the tape is pulled at a speed of 10mm/min. Compared with SBR/CMC, PAA belongs to line bonding, which has a higher degree of particle anchoring and stronger cohesion of pole sheet, which is conducive to structural stability, which is specifically reflected in the high compaction density of 0.1 or more. SBR/CMC focuses on point-to-point bonding between particles, the rebound after compaction and the expansion rate after liquid injection are higher than PAA. Aqueous PAA contains a higher proportion of strong polar group pairs such as sodium carboxylate, which has better bonding effect on fluid collection.

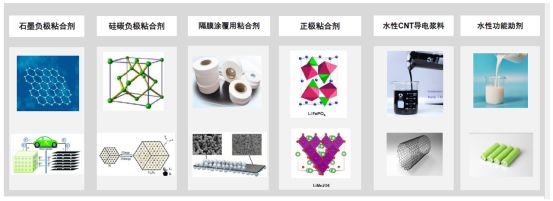

Secondly, the EIS impedance spectrum of the binder shows that the presence of polar groups such as sodium carboxylate contributes to ion conduction in lithium-ion batteries, which is helpful for impedance reduction and magnanimity performance, and the impedance of PAA is lower than that of SBR/CMC. PAA, in the electrolyte swelling small, in the electrolyte to maintain a high strength; It has a higher membrane strength, which is helpful for the long cycle of lithium-ion batteries. PAA is widely used, at present, energy storage battery graphite, power battery silicon carbon, diaphragm coating, positive electrode adhesive and other fields can be used.

For example, making a battery in lithium manganate usually has a disadvantage, that is, poor high temperature performance, if lithium manganate does a 60 degree cycle decay quickly, but PAA can be used in the positive electrode, just said is used in the negative graphite, but when used in the positive electrode, lithium manganate is neutral, lithium iron phosphate is also it is not alkaline like terene lithium. If it is neutral, water is used as a solvent, plus sodium polyacrylate, after doing this system, the high temperature performance of lithium manganate batteries will be greatly improved, and the shortcomings of its poor high temperature performance will be solved by the adhesive of sodium polyacrylate. Through the example of lithium manganate, it is proved that sodium polyacrylate is also very big advantage. Zhang Guiping concluded that PAA has many advantages over conventional binders: 1. Improve the bonding strength of the electrode material and extend the cycle life of the battery cell; 2.PAA water positive electrode improves the cycling stability of lithium manganate at a high temperature of 60 degrees, and it is estimated that -COONa can inhibit the dissolution of manganese at high temperature. At the end of the speech, Zhang Guiping expressed confidence that sodium polyacrylate will be very large applications in the future. Statement: This article is based on the live speech shorthand content integration and release, without review (Source: Starting Lithium) |