Will silicon be the next generation of anode materials to replace graphite?Issuing time:2023-10-09 12:52 After several years of development, the power battery technology of new energy vehicles has also been rapidly developed, and the battery life has been increased from 100 kilometers of the earliest electric vehicles to more than 600 kilometers at present. However, as a means of transportation, the actual driving range of long-distance travel is usually reduced by about 50 to 150 kilometers. Major electric manufacturers solve this problem mainly by using high-nickel ternary (nickel-cobalt-manganese) cathode materials, which can greatly improve the energy density of power batteries. However, in addition to the use of higher energy density positive electrode materials, negative electrode materials as one of the "three major parts" of lithium batteries, and positive electrode materials, electrolytes are equally important.

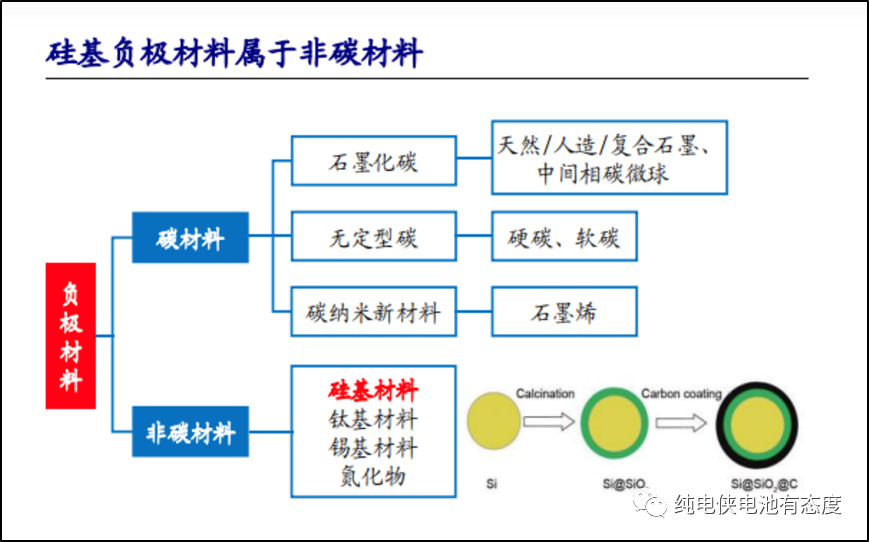

In the process of lithium battery charging, the negative electrode material, as the carrier of lithium ions and electrons from the positive electrode, has the role of energy storage and release. And in the battery cost, the negative electrode material accounts for 5%-15%, which shows its importance in the lithium electronic battery system. Therefore, some manufacturers have introduced silicon as a negative electrode material to improve battery life. The current commercial mass production of lithium battery anode materials are mainly graphite anode, which is divided into natural graphite and artificial graphite. However, despite the improvement of the process, the specific capacity of graphite has reached the physical limit of the material - 370mAh/g, which has been unable to meet the increasing demand for lithium batteries.

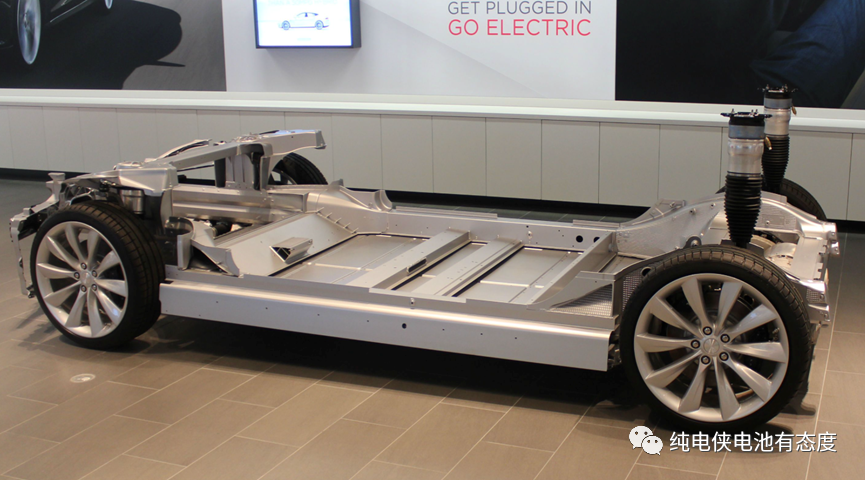

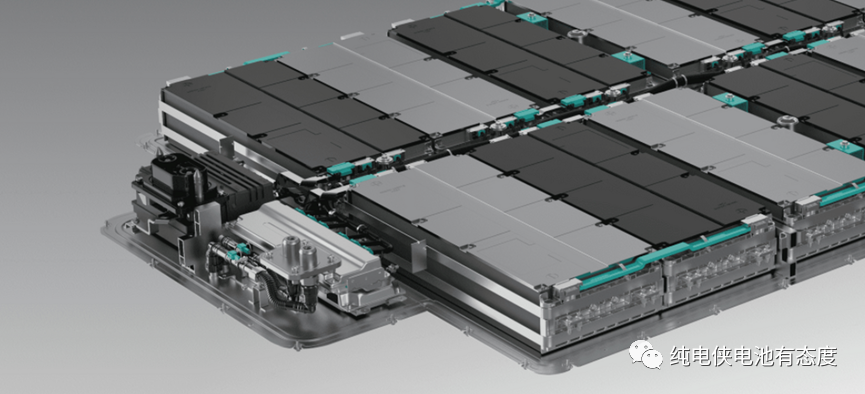

In such an industrial situation, the innovation of negative electrode materials is a breakthrough, and silicon-based negative electrode materials have become the focus. However, the negative electrode cost of pure silicon material is too high, which is more than 3 times that of graphite, so the mainstream solution is to use silicon oxygen and silicon carbon together with graphite, which can make the negative electrode reach the maximum specific capacity of 650mAh/g. For example, Tesla previously incorporated about 10% silicon into the 2170 battery in the Model 3, greatly improving the battery performance. Domestic enterprises have also strengthened the research and development of silicon negative battery technology, including battery manufacturers such as Ningde Times, BYD, and Guoxun High-tech, have invested in the research and development of silicon negative batteries.

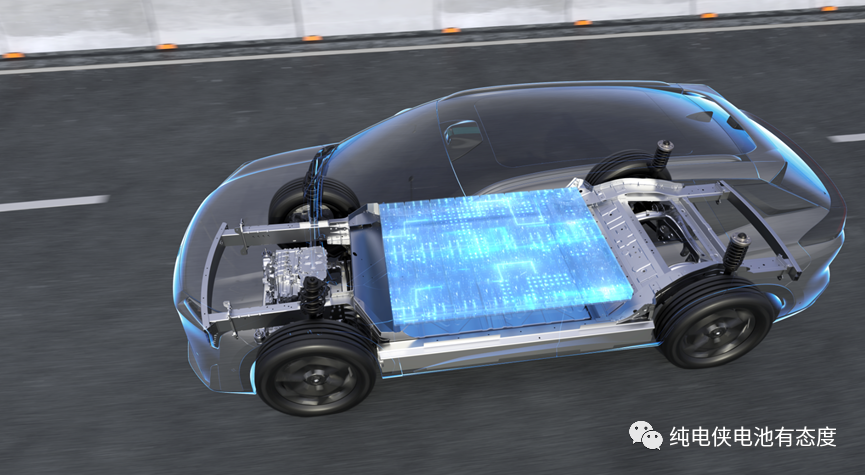

Although silicon based anode material technology has been gradually mentioned by many companies, the technical progress is far less than expected. Data show that in 2022, shipments of negative electrode materials in China reached 1.37 million tons, and the market is still dominated by natural graphite negative materials and artificial graphite negative materials, of which artificial graphite negative materials account for the highest proportion. The proportion of silicon-based materials is less than 3% of the total shipment of negative materials, and the volume is very small. The reason why the growth of silicon-based anode materials is slow is mainly affected by the following obstacles:

1, new energy vehicle subsidies gradually decline until completely cancelled, which undoubtedly brings more cost pressure to car companies. The battery cost of car manufacturers needs to be about 0.8 yuan /Wh to maintain normal operations, otherwise it will inevitably increase in price, thus affecting sales. The cost of silicon-based negative electrode is too high, and the expansion of use will inevitably lead to a substantial increase in cell cost. 2, the number of cell cycles of the silicon-based negative electrode is far less than the expected effect, the relevant institutions require the cell cycle of the power battery to be more than 1000 times, and the silicon-based negative electrode of most companies can only reach 400 to 500 cycles.

3, the design shape of the power battery gradually appeared square cell, soft pack cell and other ways, and the cylindrical cell is the largest market that can use silicon-based negative electrode, but the characteristics of the silicon-based negative electrode make the cylindrical battery lose its low-cost advantage, and the market itself is shrinking, so the silicon-based negative market growth is weak. Silicon-based negative electrode theoretically has better performance than graphite negative electrode, but from the current situation of the industry, at least there is no trend of large-scale use, only when the technology develops to meet the cost expectations, it is possible to load a large number of vehicles. For a long time in the future, the negative electrode material will still be mainly graphite negative. (Source: Pure Electric Man) |