Lithium ion battery electrode material adhesive: Why polyacrylic acid PAA adhesive is promising?Issuing time:2023-10-09 12:51 PAA and its salt are a water-soluble chain polymer, which can form stable compounds with metal ions, calcium, magnesium, etc. PAANa is easily soluble in water, and has many functions such as increasing, emulsifying, expanding and stabilizing. The first coulomb efficiency and cycle performance of graphite negative electrode were improved by using PAA and its salt as the binder of carbon negative electrode of ion battery. Related studies were conducted to prepare graphite anode sheets using polymethacrylic acid (PMA), polyvinyl alcohol (PVA), PAA and its salts. It was found that the lone pair electrons in the galvanic functional groups such as -COOLi and -COOH in the binder could interact with the solvated Li, which could promote the formation of SEI film on the surface of the graphite electrode. The carbon cathode based on these binders has a higher first coulomb efficiency in polycarbonate (PC) -based electrolyte than that with traditional PVDF binders. PVDF binders cannot form a stable SEI film in PC solution, and PC is easy to enter the graphite layer and cause damage to the electrode performance. When using binders containing hydroxyl oxygen atoms, some PAA salts form SEI films with solvated ions, preventing PC molecules from entering the graphite layers.

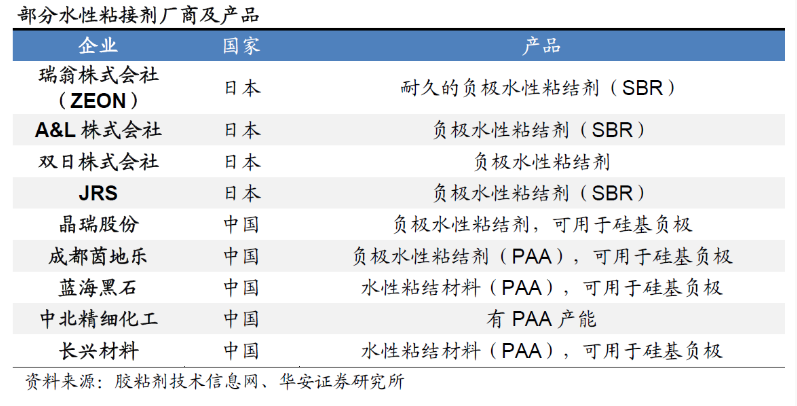

PAA salt also has obvious advantages for other negative electrode materials, and some studies have found that PAA as a silicon negative electrode binder has better performance than CMC. The addition of (15wt)% PAA to the carbon coated silicon nanoelectrode has no significant capacity reduction after 100 cycles. The effect of binder on the performance of S-C composite electrode has been studied. The discharge capacity and coulomb efficiency of the electrode made of PAA are significantly higher than that of PVDF binder, and the electrode impedance is lower when PAA is used. Studies have confirmed that the electrochemical performance of SiO composite electrode using PAA is better than that using PVDF, which may be because PAA is an amorphous polymer, and PVDF is a crystalline polymer, and the combination of PAA and SiO is better than PVDF in the amorphous region. PAA and its salts also have a positive effect on some cathode materials. It has been reported that compared with the use of PVDF, using PAA to prepare LiFePO, the specific capacity and cycling performance of the electrode have been improved to a certain extent, and the electrode's SEI film resistance and charge migration resistance are low, and the polarization is small. Some studies have found that the use of PAA binders can inhibit the rupture of LiFePO electrodes. The LiMn2O4 positive electrode sheet was prepared with PAA binder, and the performance of the electrode was improved compared with that of PVDF.

It is a new development direction for PAA to form crosslinking adhesives with other materials. PAA-CMC cross-linked binder, PAA-PVA cross-linked binder, PAA-PANI cross-linked binder, EDTA-PAA and other exploratory attempts in three-dimensional covalent cross-linked polymer, so that the composite binder and silicon surface to form a multi-point interaction, effectively prevent the separation of silicon particles, further improve the stability of the battery cycle. It is the further research direction of new adhesive. (Source: Huizheng Information) |